The PC-IP Thermal Solution

- Disruptive Packaging

- Nov 11, 2025

- 3 min read

Updated: Nov 27, 2025

An Innovative and High-Performing Cooling Solution for the Seafood Industry

PhasCore™[1], (the PC-IP solution), has been engineered to specifically handle the harshest supply chains by road, sea, rail, and air. Designed to replace wet ice or conventional gel packs, the combination of URTHCOOL® with this innovative solution results in further freight savings and excellent thermal performance. A 'phase-change cooling material' is a substance that absorbs large amounts of heat energy when it changes phase from a solid to a liquid, maintaining a relatively constant temperature during this transition and effectively providing cooling by absorbing heat from its surroundings. PC-IPs are pre-frozen and placed in URTHCOOL® boxes during the packout stage of processing, similar to any conventional gel pack, dry ice, or wet ice (DIWI) solution.

Thermal Case Study

To establish the performance of URTHCOOL boxes packed with PC-IPs, a rigorous salmon supply chain was selected as the ideal testing scenario. Over a period of six months, a series of trials subjected URTHCOOL boxes to different conditions to provide a detailed analysis of the thermal performance of URTHCOOL boxes packed with PC-IPs.

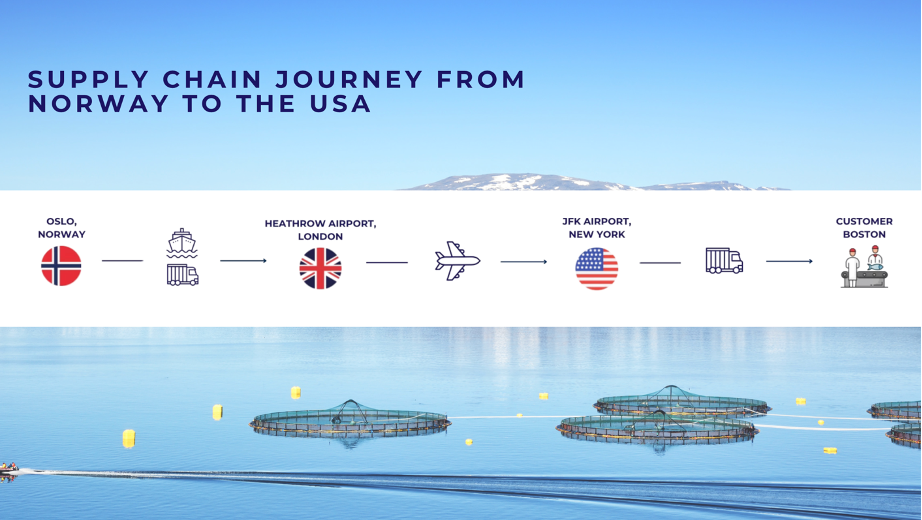

Salmon fillets were packed in URTHCOOL boxes with PC-IPs in Oslo, Norway, for a customer in Boston, USA.

The diagram below illustrates the entire supply chain and the means of transport used:

Test 1 – URTHCOOL Boxes Comparing Phase-Change Cooling MaterialsURTHCOOL boxes packed with 2kg or 3kg of PC-IP were benchmarked against URTHCOOL boxes packed with traditional DIWI.

Thermal Test Results

2kg and 3kg of PC-IP outperformed the boxes packed with traditional DIWI

The top layer boxes with exposed faces were influenced most by the ambient temperature fluctuations, and this became a key consideration in subsequent testing

Test 2 – Comparing URTHCOOL and EPS

Two URTHCOOL boxes and two EPS boxes were packed on a pallet. Following road transport, they were hand-loaded onto a full PMC for airfreight. The boxes had two faces exposed on the pallet and one face exposed on the PMC to subject them to greater potential temperature fluctuations.

Thermal Test Results

URTHCOOL boxes with PC-IPs maintained the same temperature as EPS boxes throughout the entire supply chain.

Internal temperature under the top layer of fillets maintained 0°C.

Test 3 – Pallet of URTHCOOL and EPS Together

One full pallet of URTHCOOL boxes was transported alongside pallets of EPS and loaded onto the PMC for airfreight. The boxes contained either 1.5 kg or 2 kg of PC-IPs.

Thermal Test Results

The internal temperature under the top layer of fillets did not exceed 1°C throughout the entire supply chain.

1.5 kg of PC-IPs was sufficient for the journey, while 2 kg was considered to exceed requirements.

Test 4 – PMC of URTHCOOL Boxes

An entire PMC was loaded with full pallets stacked with 45 URTHCOOL boxes, with each box packed with 1.5 kg of PC-IPs.

Thermal Test Results

External pallet temperatures spiked during unloading at JFK.

Internal temperature under the top layer of fillets remained under 2°C throughout the entire supply chain.

Thermal Testing Summary

PC-IPs have a superior weight-to-cooling ratio; that is, fewer kilograms of PC-IPs are required to provide an equal level of cooling when compared with DIWI. The significant weight savings are a critical factor to consider in airfreight supply chains. The combined solution of URTHCOOL boxes and PC-IPs offers excellent thermal support throughout the entire salmon supply chain and unparalleled freight efficiency.

[1] PhasCore™ has been developed by Phaslo, a provider of innovative cold chain logistics solutions.

Download the Application Report